Phoenix Swing Arm Robots are revolutionising robotic automation in manufacturing. Learn about its versatile applications and the future of manufacturing.

Robotic automation is reshaping the manufacturing process, and Phoenix Swing Arm Robots are at the forefront of this transformation. These advanced robots offer unmatched flexibility and precision, driving innovation and efficiency in production processes. As the future of manufacturing unfolds, Phoenix Swing Arm Robots are set to play a pivotal role in advancing automation technologies.

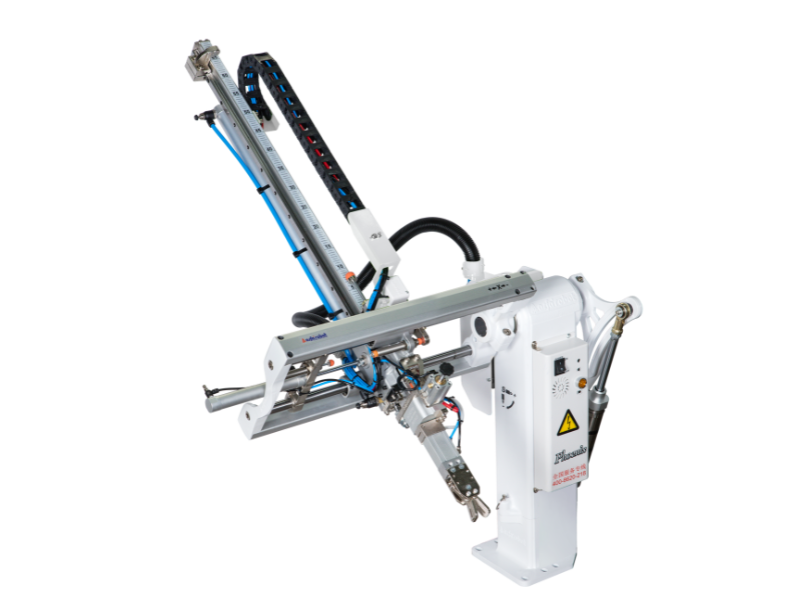

What Are Phoenix Swing Arm Robots?

Phoenix Swing Arm Robots are a type of robotic arm designed with a unique swinging motion, which allows for a broader range of movement and flexibility compared to traditional fixed-arm robots. Its distinctive design features a multi-jointed arm that swings in various directions, providing an expanded reach and the ability to access complex work areas. This design makes them ideal for applications requiring high precision and versatility.

Phoenix Swing Arm Robots in Manufacturing

The advantages of Phoenix Swing Arm Robots extend far beyond their innovative design, offering tangible benefits that can transform manufacturing operations. Here’s a look at how these robots enhance flexibility, efficiency, and overall productivity in the workplace.

• Enhanced Flexibility: The swinging arm design allows these robots to handle a wide range of tasks, from delicate assembly operations to heavy lifting. This flexibility reduces the need for multiple specialised robots and streamlines the manufacturing process.

• Improved Reach: With the ability to extend and retract their arms, Phoenix Swing Arm Robots can access hard-to-reach areas, making them ideal for intricate assembly tasks or working within confined spaces.

• Increased Efficiency: These robots can operate at high speeds and with great accuracy, leading to significant improvements in production rates and overall efficiency. Their ability to perform repetitive tasks without fatigue ensures consistent quality and reduced error rates.

• Cost-Effective Operation: By reducing the need for manual intervention and minimising errors, Phoenix Swing Arm Robots can lower operational costs. Their efficiency in performing complex tasks also helps in reducing labour costs and increasing return on investment.

Applications of Phoenix Swing Arm Robots

Phoenix Swing Arm Robots excel in various tasks within injection moulding and assembly processes, offering precision and efficiency in critical operations.

• Sprue removal: Phoenix swing arm robots are commonly used to remove sprues from injection moulding machines. Sprues are the waste material that is left over when plastic is injected into a mould. Phoenix swing arm robots can remove sprues quickly and efficiently, without damaging the parts.

• Parts removal: Phoenix swing arm robots can also be used to remove parts from injection moulding machines. This can be done either manually or automatically.

• Assembly: Phoenix swing arm robots can be used to assemble parts. This can be done by using a gripper to pick up parts and place them in the correct position.

The Future of Robotic Automation

As the manufacturing industry continues to embrace automation, Phoenix Swing Arm Robots are poised to play an even greater role in shaping the future of production. With advancements in artificial intelligence and machine learning, these robots are expected to become even more intelligent, and capable of learning and adapting to new tasks with minimal human intervention.

By embracing the power of swing arm robots, manufacturers can future-proof their operations, stay ahead of the competition and drive innovation in their respective fields. Available at BES Sales, contact us for more information.