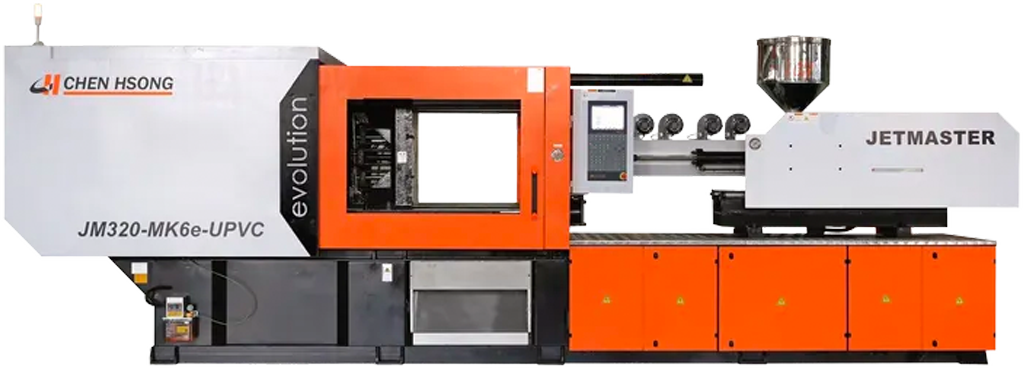

BES Sales offers Chen Hsong JM-UPVC, a cutting-edge solution that optimises UPVC processing efficiency for manufacturers in Australia. Explore its key features.

The Chen Hsong JM-UPVC injection moulding machine, offered by BES Sales in Australia, is revolutionising UPVC processing for modern manufacturers. Engineered for precision and efficiency, this advanced solution optimises production, delivering consistent, high-quality results.

What is Chen Hsong JM-UPVC?

The Chen Hsong JM-UPVC is an advanced injection moulding machine specifically designed for processing UPVC (Unplasticized Polyvinyl Chloride) materials. Chen Hsong, a renowned manufacturer in the injection moulding industry, developed this machine to address the unique challenges of moulding UPVC, which is known for its high rigidity, resistance to chemicals, and excellent durability.

Some notable features of Chen Hsong JM-UPVC are as follows.

• Specialised Designed: The JM-UPVC series is engineered to handle the high-temperature sensitivity of UPVC materials. UPVC tends to degrade or burn easily if exposed to excessive heat, so this machine provides precise temperature control to prevent such issues. It even has a specialised screw and barrel design to ensure uniform processing of UPVC material.

• Toggle Clamp System: The toggle clamp system found in this machine can significantly enhance its clamping force and stability during the injection moulding process, which improves mould accuracy and reduces cycle times.

• Optimised Plasticising System: This machine features an optimised plasticising unit that ensures uniform melting and mixing of UPVC. This helps in achieving consistent part quality, with minimal material degradation.

• High-Precision Injection Control: The JM-UPVC model is equipped with advanced hydraulic systems and servo motors that offer precise injection control, guaranteeing accurate and repeatable production of UPVC parts that are crucial for maintaining tight tolerances.

• Energy Efficiency: Like many modern Chen Hsong machines, the JM-UPVC series integrates energy-saving technologies, such as servo-hydraulic pumps, to reduce energy consumption without compromising performance.

• User-Friendly Interface: The machine comes with an easy-to-use control system, often featuring touchscreen interfaces, which allows operators to set parameters, monitor processes, and troubleshoot issues efficiently.

• Versatile Clamp Force Range: The JM-UPVC offers a range of clamp forces from 160-650T, which makes it suitable for various UPVC applications. It allows manufacturers like you to produce a wide range of products, from small components to larger assemblies.

Chen Hsong JM-UPVC: Applications

The Chen Hsong JM-UPVC injection moulding machine is ideal for producing a wide range of UPVC products. First, it can be widely used for producing UPVC construction and plumbing parts. It can also be used to make UPVC windows, door components, electrical conduits, and industrial components.

When you take advantage of Chen Hsong JM-UPVC, expect your UPVC parts to be consistent and of high quality with minimal defects. You can also make sure that the produced components will require less maintenance needs, making sure they last for a long time. Lastly, using this machine lets you carry out UPVC moulding without wasting too much money and energy, minimising waste and cost.

The Chen Hsong JM-UPVC injection moulding machine is a highly efficient and reliable solution for businesses looking to produce high-quality UPVC parts. To invest in this product, simply contact BES Sales to help you manufacture durable and precise plastic components today.