Automate injection moulding processes using Alfa Robots from BES Sales, engineered for accuracy and consistency in Australian factory demands.

Alfa Robots’ Role in High-Volume Moulding Applications

Production scalability in injection moulding depends on automated solutions that maintain uniformity across extensive manufacturing runs. At BES Sales, the Alfa Robots range includes systems engineered to sustain consistent output levels, even under prolonged operational demands. Each robotic unit is configured to support uninterrupted cycle execution while preserving the dimensional fidelity of every moulded component.

Reliable automation enables reduced rejection rates and enhanced surface finish across complex part geometries. Integration of Alfa Robots promotes streamlined workflow transitions, supporting adaptive performance in alignment with customer-specific production targets.

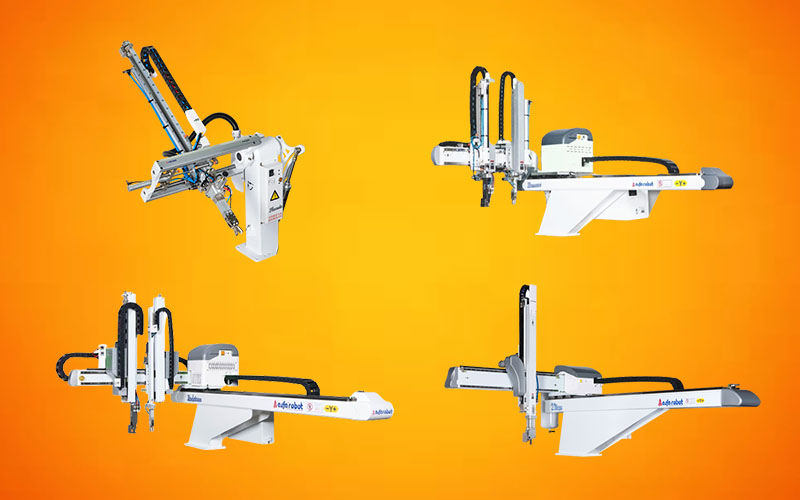

The following Alfa Robots are available from BES Sales:

• Redstone Series

• Phoenix Series

• Titan Series

• Bomarc Series

Alfa Robots in Australian Manufacturing Standards Compliance

Maintaining alignment with national compliance benchmarks demands unwavering quality and safety protocols. These machines provide reliable traceability across production stages, allowing audits and quality assurance reviews to proceed with reduced disruption.

Australian regulations covering safety, electrical control, and machine guarding are addressed through Alfa Robots’ integration. Systems operate within performance bands that match or exceed local legislation, reducing the risk of regulatory penalties.

Reducing Downtime with Predictive Robotic Maintenance

Predictive technologies embedded in Alfa Robots help prevent unplanned downtime by identifying performance variances before failure occurs. These systems apply real-time analytics to monitor mechanical conditions, allowing informed decisions that maintain continuous operation.

• Real-Time Monitoring: Sensors continuously collect data on motion sequences, cycle speed, and thermal output. This information provides live feedback that helps adjust operations before mechanical limits are reached.

• Failure Forecasting: Advanced diagnostic software analyses operational data to detect irregularities linked to wear and stress. Forecasts based on this data reduce reliance on reactive maintenance and emergency shutdowns.

• Component Life Tracking: Each robotic component is assessed individually for lifecycle wear and mechanical fatigue. This enables scheduled part replacement without affecting production timelines.

• Automatic Alerts and Reporting: The system generates service alerts supported by detailed performance logs. This facilitates precise maintenance scheduling and reduces technician guesswork.

• Maintenance Scheduling Integration: Maintenance intervals are dynamically adjusted according to equipment usage and load conditions. This ensures servicing is aligned with actual wear rather than fixed calendar intervals.

Precision in Every Cycle: BES Sales Driv es Moulding Efficiency

Driven by the needs of modern manufacturing, BES Sales supplies injection moulding machinery engineered for high-output performance and long-term reliability. The Alfa Robots range supports Australian factories seeking automation solutions that improve consistency, reduce downtime, and align with production targets.

Trust BES Sales for advanced Alfa IMM take-out robotics range that support efficient, large-scale injection moulding with reliable and consistent performance.

Explore Alfarobot to find dependable robotic arms tailored for injection moulding—an ideal choice for precision-driven production environments.