Improve production lines through Phoenix Swing Arm Robots. Available at BES Sales, discover how they enhance efficiency, maximise uptime, and ensure quality.

Phoenix Swing Arm Robots are one of the innovations that can optimise manufacturing processes. These products offer an unparalleled solution to keep production lines moving smoothly and efficiently. Explore how these robotic systems change the game in manufacturing, providing the precision and reliability businesses require to stay ahead.

The Emergence of Robotic Automation

Robotic automation has become pivotal in modern manufacturing, offering solutions that increase productivity, reduce errors, and improve safety. Among these innovations, Phoenix Swing Arm Robots have carved a niche for themselves, thanks to their unique design and capabilities. These robots are specifically designed to enhance the operational efficiency of production lines, making them a critical asset for manufacturers worldwide.

Phoenix Swing Arm Robots: Features

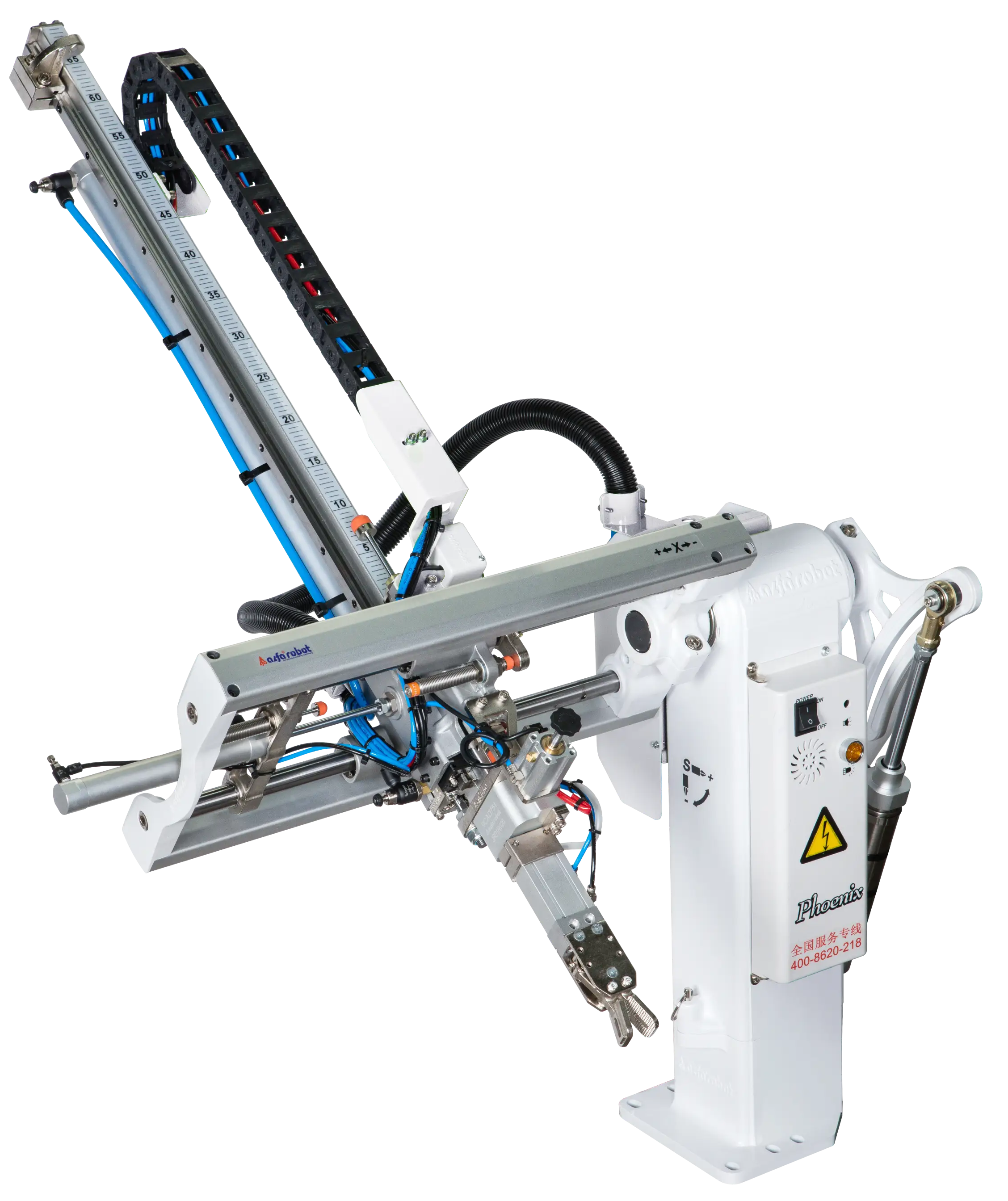

One of the standout features of the Phoenix Swing Arm Robots is their versatility. These robots are adept at handling a wide range of tasks such as removing finished products and sprue. Their swing arm design allows for a compact footprint, which makes them ideal for environments where space is at a premium. They can also be adjusted by loosening the fixed handle for easy tool change. Their adjustability allows these swing arm robots to adapt to various tasks without significant downtime for reconfiguration.

Now, the hallmark of Phoenix Swing Arm Robots is their ability to maximise uptime. These robots are engineered to perform repetitive tasks with high precision, reducing the likelihood of bottlenecks that can halt production. By ensuring consistent operation, they help factories maintain a steady flow of output, thereby maximising productivity.

Phoenix Swing Arm Robots are compatible with 30-300ton horizontal injection moulding machines. Their rotary assembly mechanism then allows for the rotation of products at 90 degrees. They likewise feature high rigidity linear slide rail and aluminium alloy structural beam, which allows them to last for a long time.

Maximise Phoenix Swing Arm Robots

BES Sales offers Phoenix Swing Arm Robots to manufacturing plants that want to improve their production and ensure safety.

Quality control is an area where Phoenix Swing Arm Robots shine. In manual operations, the risk of human error can lead to inconsistencies in product quality. However, these robots deliver uniform performance, making sure each product meets the same high standards. Their precision reduces waste and rework, contributing to a more sustainable and cost-effective production process.

Integrating Phoenix Swing Arm Robots into the production line also enhances worker safety. By automating tasks that are repetitive, strenuous, or potentially hazardous, these robots reduce the risk of injuries and allow human workers to focus on more complex and safer tasks. It not only improves the overall working conditions but also boosts morale and productivity among the workforce.

With Phoenix Swing Arm Robots, expect to increase your productivity by 20%-30%, reduce product defect rate, ensure operator safety, reduce labour cost, control production, and cut waste. Optimise your production today by contacting BES Sales.